ASTRO Barcelona Racing Equipment

mail@astrobcn.com

Bicycle saddle Carbon rails

To reach a 100 gr. all-up weight saddle, was the requirement of the Carbon/Epoxy rails for a racing bicycle saddle. For this project we

developed the manufacturing process on a closed aluminium mould with electrical heating. The peak temperature was regulated by

programmable thermostat for the resin to work at its maximum performance. We worked on:

- Industrialization Engineering,

- Design of the mould with thermostatically controlled heating,

- 3D modelling for CNC machining of the mould,

- 100% Carbon monolithic lamination.

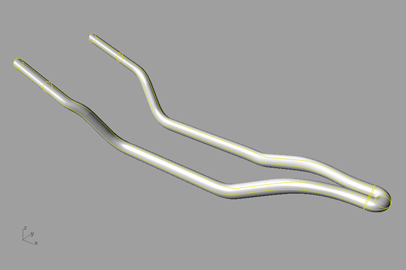

Preliminary 3D model

Preliminary 3D model

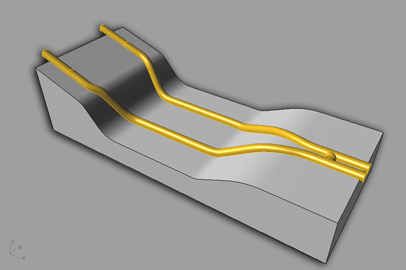

Parting line approach and 3D mould model

Parting line approach and 3D mould model

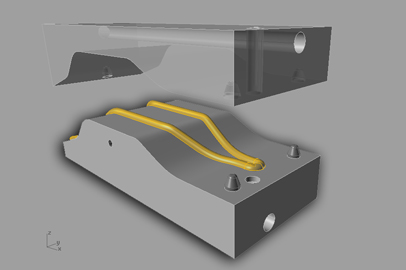

Final mould 3D model

Final mould 3D model

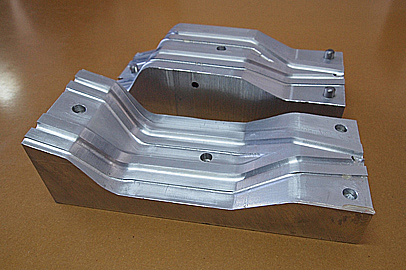

Prototype mould

Prototype mould

First prototype

First prototype